The drivers provide instructions to the motors, which control each axis to create models. The controller then directs the central breakout board which in turn sends instructions to the drivers, based on the information provided by the software. The CNC control software is directly connected to the CNC controller with a transfer protocol, usually a parallel DB25 port or USB. Some software allow you to edit and input your g-code, known as g-code manipulation, while others – g-code sender software – simply send out the code to the firmware.

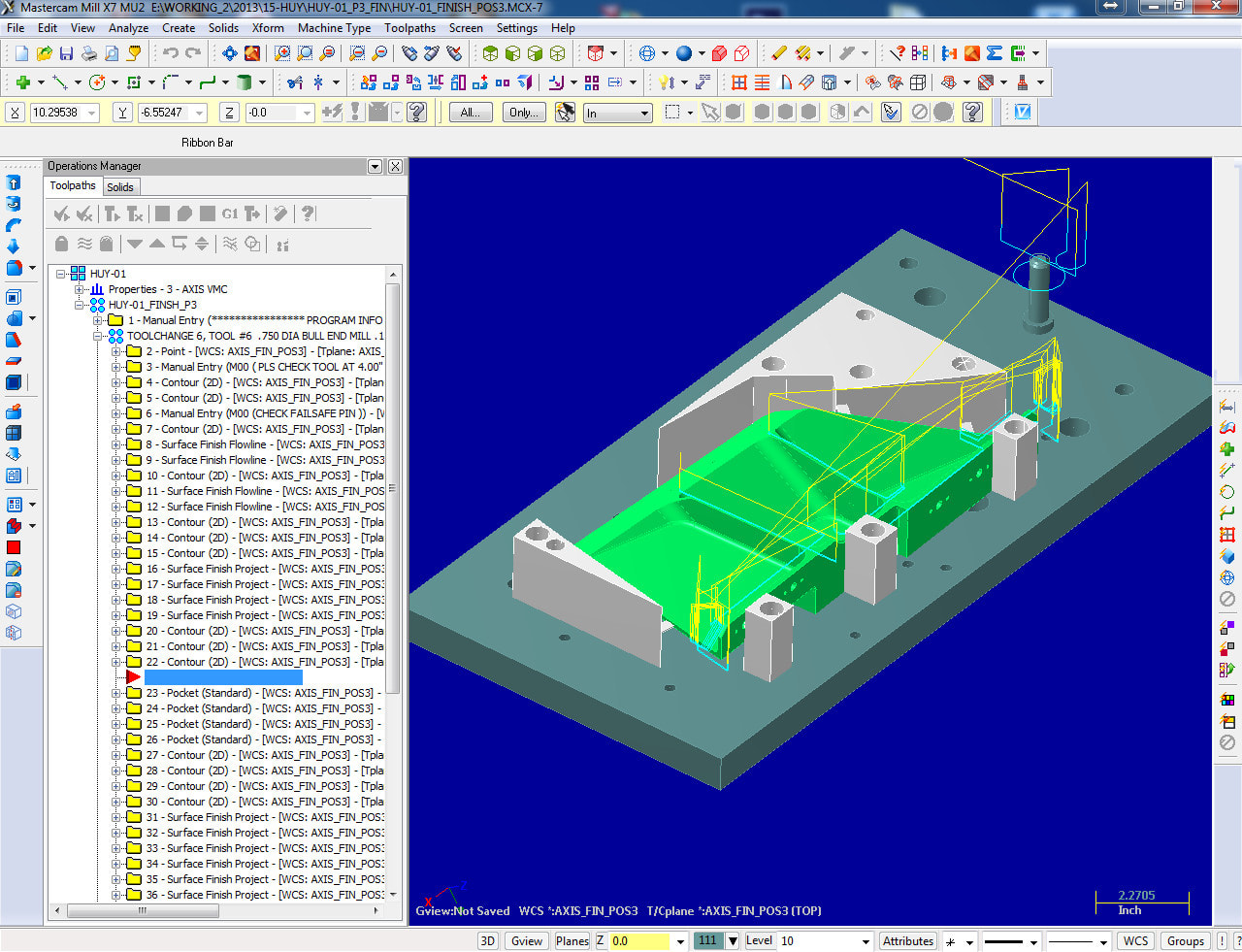

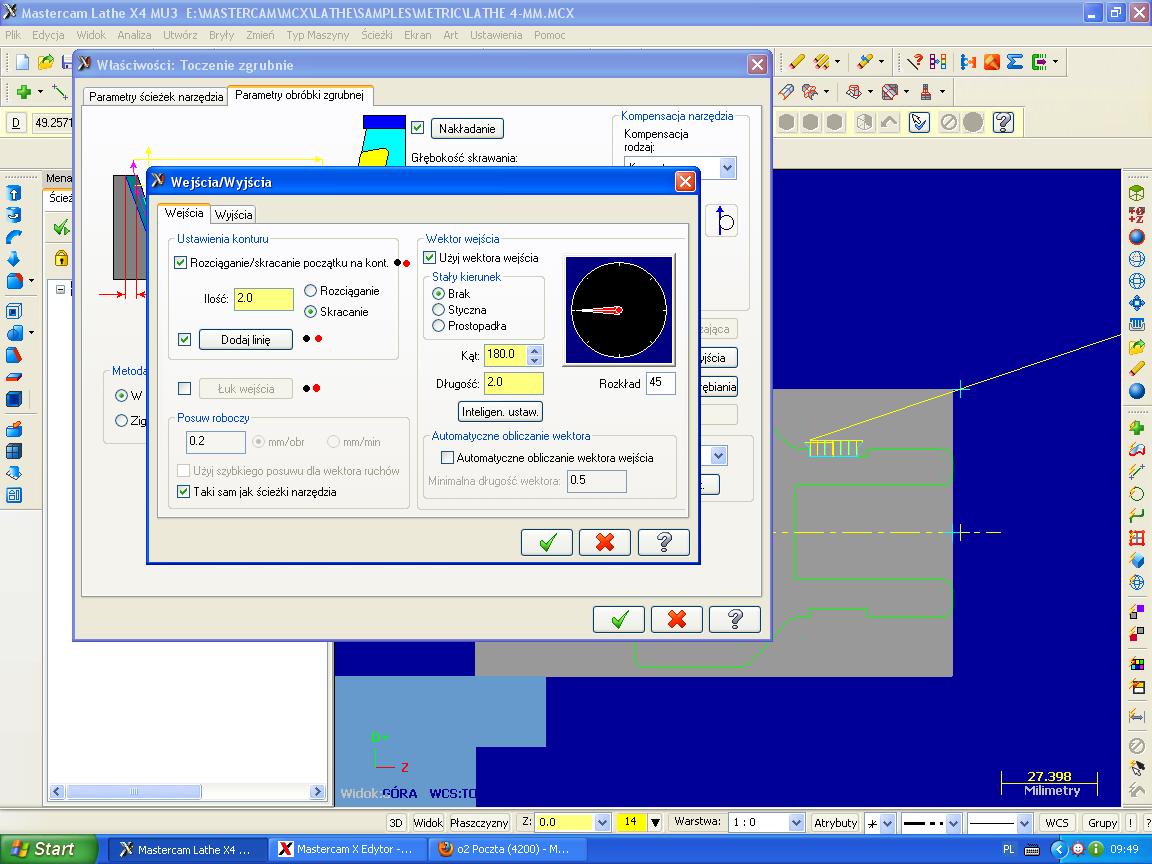

G-code is the most widely used CNC programming format and essentially provides information to the CNC machine about what work needs to be done. You then need to use CAM software, which takes your CAD drawing file and creates a g-code. You can think of this as a blueprint for your design.Īnything you can design, you can make a reality with the right CNC design software, whether it’s a simple piece of woodwork or intricate, laser-cut fine jewelry. The first step in the process is to create a design using CAD (computer-aided design software), which is separate to the CNC programming software. Here’s a quick view of the best CNC router software:įree CNC controller software / G-code software for CNC:īest CNC controller software (professional): But before we get into that, let’s take a closer look at how CNC software works. We take a close look at the key aspects of each software to help you make the right choice.

To help you out, in this guide we reveal the very best CNC software available right now, including both free and paid software. While there are free CNC software that can be used by anyone, some of the best software can cost hundreds of dollars, so you need to find a program that’s within your budget.

0 kommentar(er)

0 kommentar(er)